Does a mould-making company need to know the material and the target industry of the mould it has to design? Of course!

Does a mould-making company need to know the material and the target industry of the mould it has to design? Of course!

Every industry and every material requires very specific knowledge and the perfect result is achieved when there is perfect cooperation between the parties.

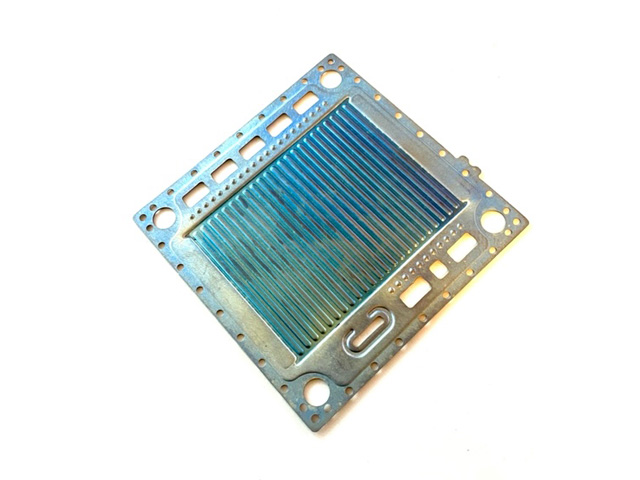

Subsequently, blanks were produced in Grade 2 Titanium sheet metal by Waterjet cutting.

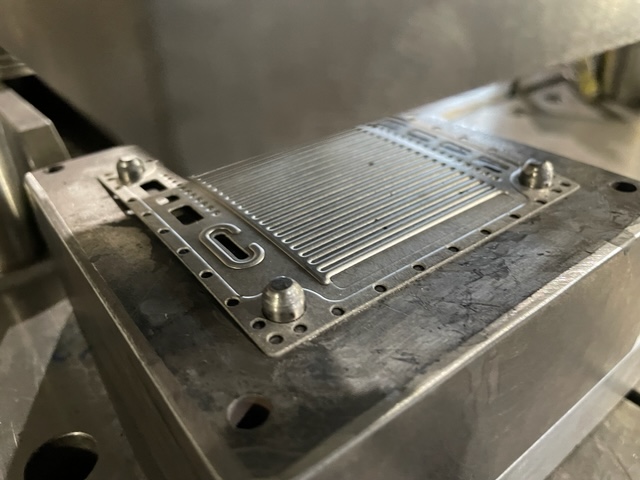

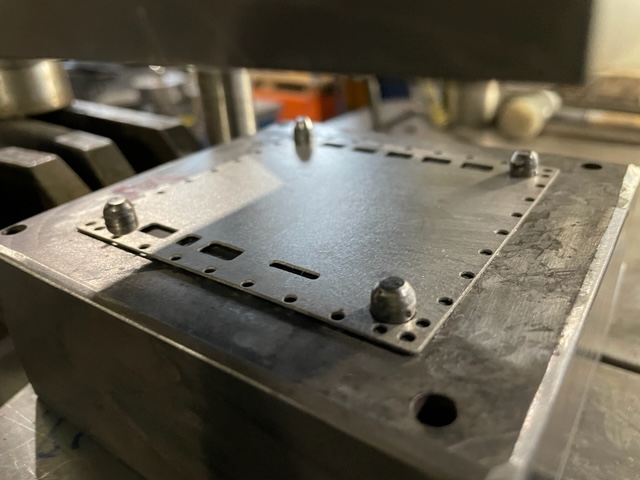

Once the blanks were machined under the mould on a hydraulic press, we performed a stress relieving process in an oven, again with the aid of equipment to help hold the components in shape.

The result was perfect and the customer was satisfied with our products and services.